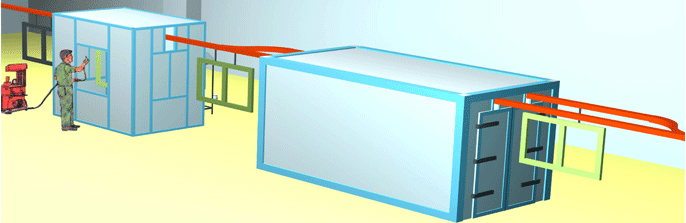

Consultech manufacture a complete range of uniquely designed modular Powder Coating Booth and systems for both manual and fully automatic coating applications. We have several years experience in the design, manufacture, installation, commissioning and service support of powder coating systems and equipment. We have various Powder Coating Booths models along with wide range of Powder Coating Ovens.

Highest efficiency in a Powder Coating Booth is always attained when the capacity, size and other specifications are most suited to the kind of work to be performed.

The following factors are important while selecting the most appropriate booth for a specific coating component.

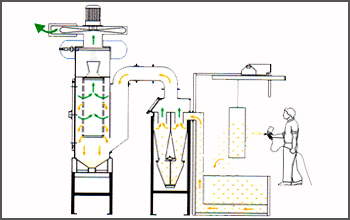

The powder coated spray chamber with the multi-cyclone recovery gives almost 98% powder utilization. It is maintenance free and has a very long life. The powder booth is easy to clean, resulting, in a quick color change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone result in pollution control.

Maximum powder efficiency of 98.5% with a very good life gives the Multicyclone an edge over other powder recovery systems. The high velocity of powder in the multicyclone reduces powder sticking, so cleaning time is negligible. Over sprayed powder is then sucked in by the blower through a cyclone recovery system, powder collected in the bottom bin, can be reused.

Multi-cyclone helps in maximum utilization of chargeable powder. Very fine powder which is less than 0.5 micron (does not catch static charge) need to exhaust as per the pollution control laws, required to be arrested. The post filter arrests this powder and gives out breathable air.

A number of filter cartridge are mounted inside the sealed metallic chamber. The air enters the chamber and the filtration occurs ‘outside in’. Periodic purge removes the powder and clean the cartridge. Clean air is given out through the blower outlet.

Bag filter is also used for recollecting such useless powder. These bags are made of non oven filter media.

Consultech are the leaders in manufacturing of Powder Coating Ovens. The technical specifications, design, manufacturing, installation and commissioning process is offered as a complete package. Our Powder Coating Ovens are preferably suitable for a wide range of powder coating and are available in many different sizes, types and temperature ranges.

Consultech Powder Coating Ovens are renowned throughout the variety of industrial heating application as the best ovens currently available. These ovens are available in a range of temperature are all pre-assembled, wired and tested prior to dispatch. The heating media are used with Gas, Diesel, Electricity or Thermic fluid/Steam. All ovens are constructed from high quality components using our unique modular construction method.

We have batch box type oven had wide range and readily available. Medium and big size industrial oven are built in Modular cassette and expandable construction. A unique feature of these oven are the World class Rockwool insulation for minimum heat loss.